PV-271 Pump Drive

Drill Faster with Reliable Gearbox Exchange.

A failed Pump Drive Gearbox on your Epiroc Pit Viper 271 means costly downtime and halted operations.

Waiting for repairs or new components can take valuable time you don't have.

Our Service Exchange Program offers a rapid, reliable, and cost-effective solution to get your essential drilling equipment back online fast.

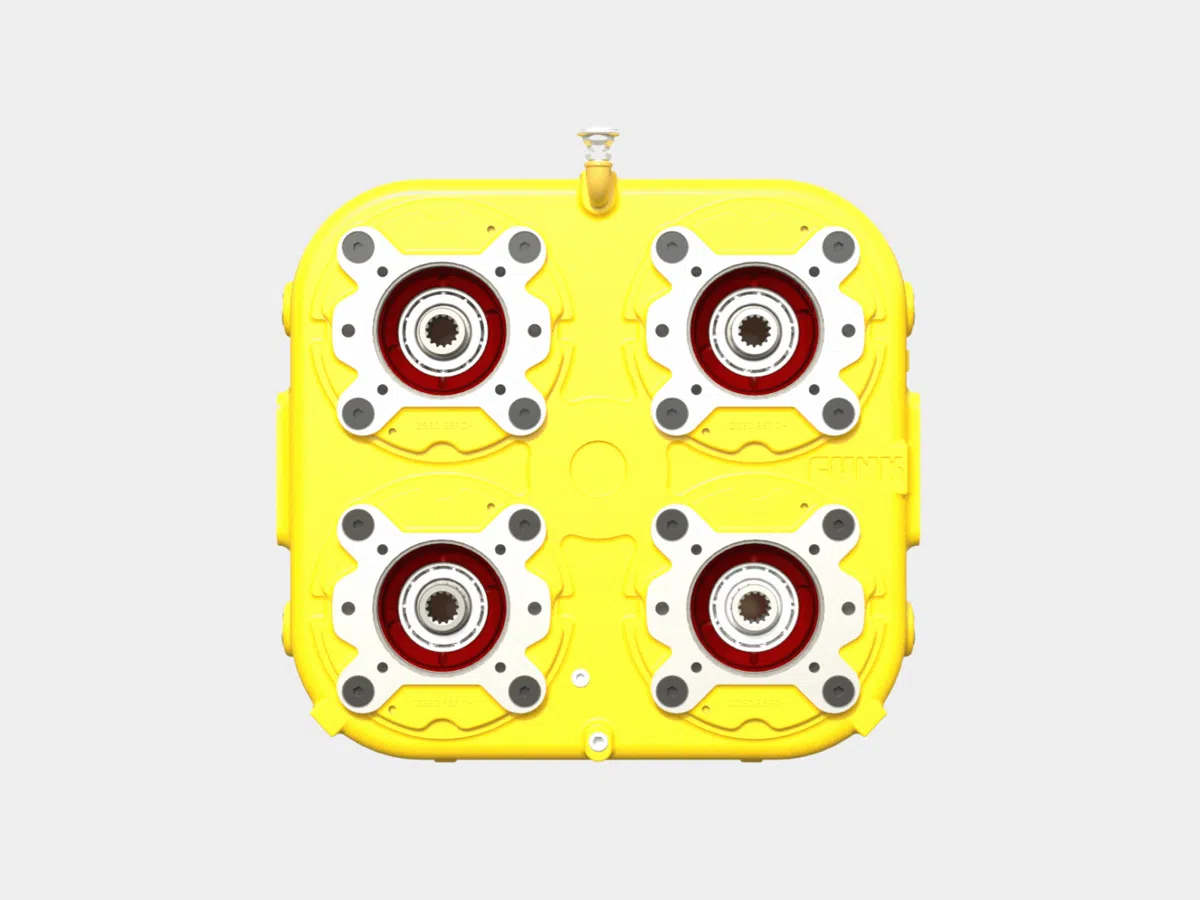

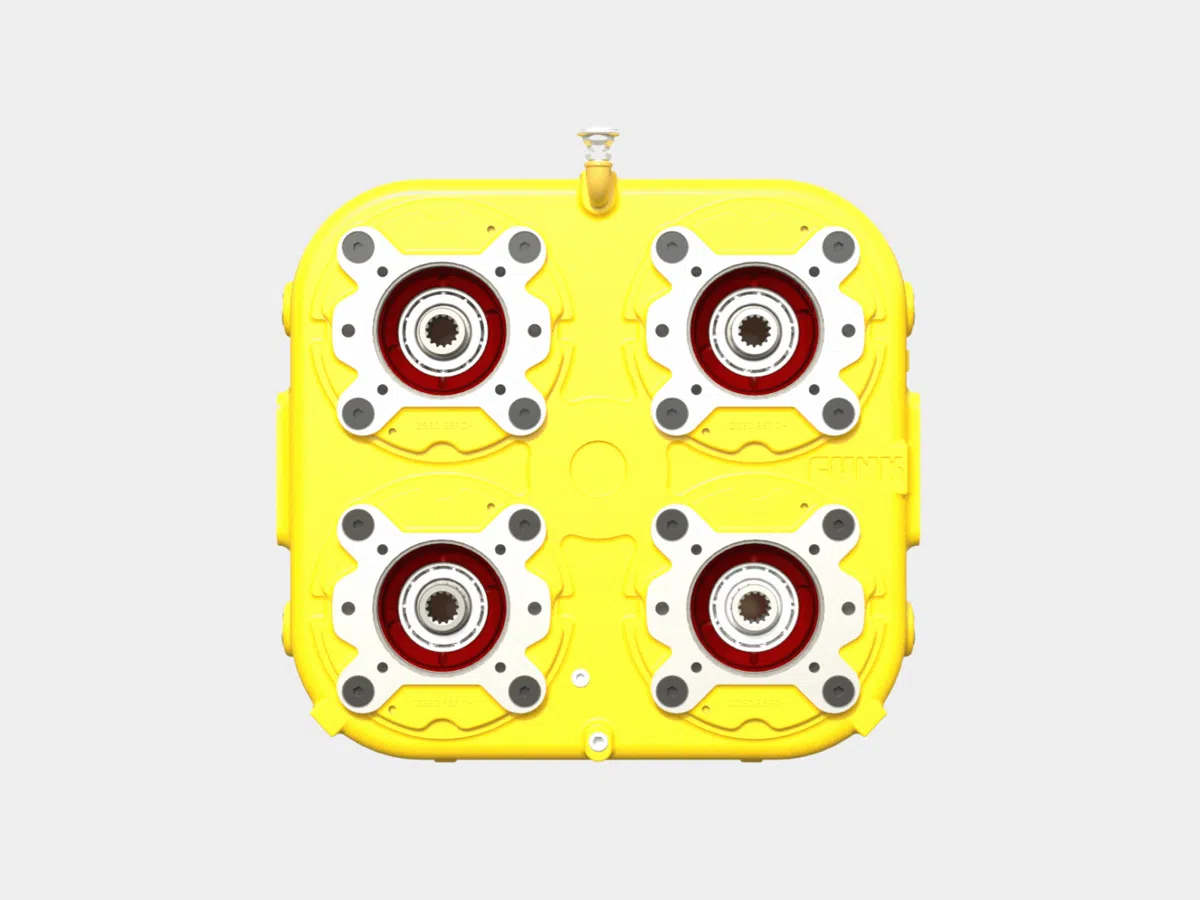

Epiroc Pit Viper 271 Pump Drive Gearbox

Minimise Downtime with a Service Exchange PV-271 RCS5 Pump Drive.

Epiroc Part No. 2659605201

Epiroc Part No. 2659605201

A critical failure in the PV-271 pump drive can bring your entire drill and blast program to a halt.

Our service exchange gearboxes are rebuilt to meet or exceed OEM specifications, with upgrades that address known weak points and keep you drilling longer.

Have a ready-to-install unit dispatched from our WA workshop and get your rig back on the bench increasing metre count in no time.

5 Star Quality Build

PV271 Pump Drive is precision-engineered to support your drill rig's performance and deliver results you can count on.

5 Star Service Exchange Components

Service Exchange PV-271 RCS5 Pump Drive

The Strategic OEM Alternative

OEM lead times and replacement costs can put significant pressure on your maintenance budget.

Our service exchange program offers a cost-effective, strategic alternative. We are expanding our range of Epiroc Pit Viper Pump Drives with the RCS5 PTO Quad Box.

Rebuilt to OEM specification & focused on durability, these gearboxes are engineered to withstand the harsh demands of the Pilbara.

Plan your next component change-out with a CFM rebuilt unit to enhance reliability and control costs.

5 Star Service Exchange Components

Service Exchange PV-271 RCS5 Pump Drive

The Strategic OEM Alternative

OEM lead times and replacement costs can put significant pressure on your maintenance budget.

Our service exchange program offers a cost-effective, strategic alternative. We have expanded our range of Epiroc Pit Viper Pump Drives to include the Pit Viper RCS5 Drill Rig PTO Quad Box.

Rebuilt to OEM specification & focused on durability, these gearboxes are engineered to withstand the harsh demands of the Pilbara.

Plan your next component change-out with a CFM rebuilt unit to ensure your Pit Vipers Hydraulics are Driven by Performance & Quality.

5 Star Rebuilt Component

Reman PV-271 Gearboxes: Meeting & Exceeding OEM Standards

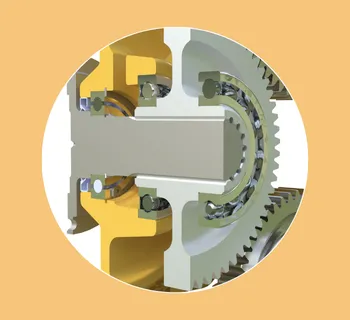

Improved Design

Our gearbox's address a common failure point by engineering a lengthened input shaft.

This ensures full spline engagement with the input gear, reducing premature wear and extending the component's service life.

Contact our Team & Upgrade Now!

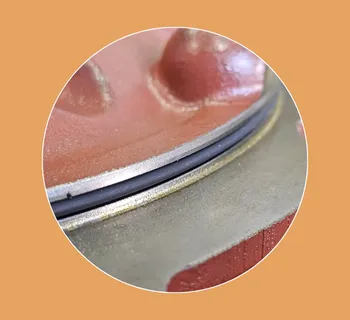

Leak Protection

To prevent fluid leaks under operational pressure and vibration, each pump adapter plate is meticulously assembled using high quality o-rings and flange sealant.

Get a Quote Today!

Eliminate Dust Entry

To combat dust ingress in abrasive site conditions, every gearbox is fitted with an oil dipstick featuring a positive twist-lock seal, protecting critical internal components from contamination.

Need it Now - Order Yours Today!

Need it Now - Order Yours Today!

WA-Based Expertise, Engineered for Reliability

Our specialist rebuild program delivers a Cost-Effective, Reliable Alternative to New OEM components.

Pit Viper Components You Can Rely On

Service Exchange Rebuilds Managed in WA

Our service exchange program for the PV-271 is built on a foundation of quality and local expertise.

We source and manage all essential components for a comprehensive service exchange rebuild—including premium bearings, seals, shafts, and gear sets.

By controlling the entire process in our WA workshop, we ensure every gearbox meets our stringent quality standards, delivering a reliable and cost-effective alternative to a New OEM part.

Built to Spec - Verified for Quality

We follow strict procedures, ensuring every gearbox is rebuilt to unmatched standards of reliability.

Detailed Inspections

Every core return undergoes a rigorous strip-and-report inspection by our qualified tradespeople.

We provide a detailed report documenting the core condition, ensuring full transparency in our exchange program.

Superior Workmanship

Our commitment to quality workmanship is evident in every step. From meticulous component assessment to final assembly and testing, our team adheres to strict procedures that ensure a reliable, long-lasting rebuild.

Quality Assured

Multiple QA checks are integrated throughout our rebuild process. Before dispatch, each gearbox is verified to ensure it is ready for immediate installation and will deliver sustained performance on site.

Built to Spec - Verified for Quality

We follow strict procedures, ensuring every gearbox is rebuilt to unmatched standards of reliability.

Detailed Inspections

Each gearbox undergoes in-house inspection by qualified personnel, and includes detailed core return reports documenting the core condition.

Superior Workmanship

Pride in craftsmanship drives our team's detailed approach, achieving top-tier quality from individual components through the final finish.

Quality Assured

Our gearboxes pass multiple QA checks during rebuild and pre-dispatch, ensuring each unit is ready for sustained, reliable performance.

5 Star Customers

What Some of Our Clients are Saying

Quotes from Our Google Reviews

What Our Clients are Saying

Harry and the team at CFM are a notch above the rest. Their customer service exceeded my expectations. Their knowledge & expertise in their field was outstanding. Greatly appreciate you going over and above to help. Highly recommended company.

Melinda Monaco

5 Star Customer

Harry and the team at CFM are a fantastic local company and are a highly valued sponsors of the South Lake Dolphins Swimming Club. With the support of CFM the club has been able to acquire training equipment to make our swimmers more competitive and the equipment cage that Harry and his team constructed is used daily.

Caroline Mcivor

5 Star Customer

We’ve been working with Harry and his team now for a number of years with great success. Great services and reliability, along with competitive pricing. Thanks to the CFM team.

Graham Napier

5 Star Customer

We needed a critical component for one of our contour drills on site so I emailed the team at CFM with a brief description and the model of drill. Within in an hour I had a reply with a quote, the next morning the part was on a truck Pilbara bound! Outstanding service from Bevan and the team. Look forward to dealing with CFM again!

Benjamin Woodside

5 Star Customer

CFM is a great company with great people. I visit the depo everyday to serve lunch and drinks to the team and they are always very welcoming and friendly. I would highly recommend their services.🛠️👷🏼

Caitlin Bone

5 Star Customer

CFM is a top-notch company! They really know their products and deliver services on time, every time. The staff were excellent to deal with—friendly, professional, and knowledgeable. Highly recommended!

Simon Ash

5 Star Customer